INDUSTRIAL WATER AND WASTEWATER TREATMENT

From Compliance To Circularity: Rethinking Chromium Management In Chrome Tanning

From Compliance To Circularity: Rethinking Chromium Management In Chrome Tanning

In an industrial landscape increasingly shaped by lifecycle accountability, material traceability, and rising disposal costs, chromium recovery is not merely a technical alternative — it is a strategic upgrade, where wastewater can become a resource stream.

WATER AND WASTEWATER SOLUTIONS FOR THE OIL AND GAS INDUSTRY

-

Flow Meter Helps HollyFrontier's Woods Cross Refinery Measure Flare Gas For Safety And Environmental Compliance

When the plant team at HollyFrontier’s Woods Cross Refinery, near Bountiful, Utah, needed mass flow meters to measure flare gas to the main flare header, the team drew on its past metering experiences for this difficult application.

-

Capacitance Level Switches Provide Reliable Water/Oil Interface Detection

There are a number of point level approaches to measuring the interface between water and oil for water dump control in the oil and gas industry. However, each has disadvantages — manual methods introduce human error, conductivity switches are rendered inaccurate by buildup, and float switches are susceptible to wear and tear. This white paper introduces capacitance level switches as an accurate and reliable alternative for water/oil interface detection.

-

What To Know About The EPA's New Effluent Guidelines

The U.S. EPA’s recently released Preliminary 2016 Effluent Guidelines Program Plan indicates the industries and pollutants that the agency has its eyes on for potential future regulation.

-

Best Practices In Moist And Wet Gas Flow

The Wet Gas MASSter sensor is for use in applications that have a high level of moisture or condensation present in the gas flow stream that cannot otherwise be removed.

-

IDE Showcases Evaporator For SAGD Water Treatment In Canada

IDE recently hosted exclusive guided tours of its horizontal falling film evaporator for SAGD water treatment at the fabrication shop in Calgary, Alberta. Over three days more than 120 industry professionals had the opportunity to experience IDE's SAGD Horizontal Evaporator first hand.

WATER AND WASTEWATER SOLUTIONS FOR THE FOOD AND BEVERAGE INDUSTRY

-

Packaged Wastewater Treatment: A Recipe For Success

Food and beverage wastewater treatment demands often fluctuate more drastically than municipal wastewater applications in terms of biochemical oxygen demand (BOD) relating to the foods being processed or to cyclical activity. Modular, self-contained systems offer practical, cost-effective solutions to help food processors keep pace with such variability — as a total or supplemental solution. Here’s how.

-

Distillery Wastewater Byproducts Fuel Sustainability

For distilleries, high levels of biochemical oxygen demand (BOD), nitrogen, total dissolved solids (TDS), and total suspended solids (TSS) put extra pressure on optimal biological treatment requirements. Here are some techniques that can help distillers put a little extra money in the bank while meeting the challenges of environmental discharge requirements.

-

Water Disinfection At Feldschlöesschen Brewery In Switzerland

Despite meeting European drinking water standards, contamination levels at a brewery reached as high as 800 CFU/ml, prompting the brewery to seek a reliable disinfection solution to protect the integrity of its production processes.

-

5 Approaches to Treating Wastewater in Food (Meat) Production

The meat processing industry consists of two major groups - slaughterhouses and packinghouses. A slaughterhouse is a plant that harvests animals and whose main product is fresh meat as a whole or smaller meat cuts. A packinghouse is a plant that both slaughters and processes fresh meat to cured, smoked, canned and other prepared meat products.

-

Overcoming Obstacles To Increase Wastewater Capacity

It’s a scenario that is becoming more common at food and beverage facilities. The introduction of a new product to market, or a boom in sales of an existing product, prompts management to increase production capacity. While there is plenty of space for production equipment, the corresponding need for additional wastewater treatment capacity may not be readily accommodated.

WATER AND WASTEWATER SOLUTIONS FOR THE POWER GENERATION INDUSTRY

-

A Roundup Of Energy, Water, And Climate Bills In The 84th Texas Legislative Session

We’ve almost made it to the midway point of the 84th Session of the Texas Legislature. As many already know, the Texas Legislature only meets from January to May every other year, so a lot has to get done in these few months.

-

SuperDisc™ Filtration System Case Study

Glendale Heights Wastewater Treatment Plant discharges treated water to the East Branch of the DuPage River in Illinois.

-

If Israel Can Find Common Ground Around The Environment, Why Can't Texas?

Deep in the Israeli desert is an academic institute that is building peace in the region by putting nature at its center. The Arava Institute, in partnership with Ben Gurion University, brings students from Israel, Palestine, Jordan, and around the world to find common ground around environmental problems and build trust — and peace — from there.

-

A New Approach To Early Biofilm Detection

To assist industrial operators in managing and preventing biofilm, Italian start-up ALVIM Srl created a monitoring system that provides early warning detection of bacterial biofilm growing on pipelines, tanks, heat exchangers, RO membranes, and other equipment.

-

Ultrasonic Flowmeter And Solar GSM Datalogger Deliver Continuous Monitoring And Compliance For Hydroelectric Plant In Türkiye

A hydroelectric power plant in Türkiye needed to establish a system for real-time monitoring of water consumption and turbine performance to enhance its operational efficiency. Crucially, the State Water Authority also required continuous, 24/7 remote access to water usage data for supervisory and regulatory compliance.

WATER AND WASTEWATER SOLUTIONS FOR INDUSTRY

-

Flow Meter Helps HollyFrontier's Woods Cross Refinery Measure Flare Gas For Safety And Environmental Compliance

When the plant team at HollyFrontier’s Woods Cross Refinery, near Bountiful, Utah, needed mass flow meters to measure flare gas to the main flare header, the team drew on its past metering experiences for this difficult application.

-

A Roundup Of Energy, Water, And Climate Bills In The 84th Texas Legislative Session

We’ve almost made it to the midway point of the 84th Session of the Texas Legislature. As many already know, the Texas Legislature only meets from January to May every other year, so a lot has to get done in these few months.

-

Packaged Wastewater Treatment: A Recipe For Success

Food and beverage wastewater treatment demands often fluctuate more drastically than municipal wastewater applications in terms of biochemical oxygen demand (BOD) relating to the foods being processed or to cyclical activity. Modular, self-contained systems offer practical, cost-effective solutions to help food processors keep pace with such variability — as a total or supplemental solution. Here’s how.

-

Capacitance Level Switches Provide Reliable Water/Oil Interface Detection

There are a number of point level approaches to measuring the interface between water and oil for water dump control in the oil and gas industry. However, each has disadvantages — manual methods introduce human error, conductivity switches are rendered inaccurate by buildup, and float switches are susceptible to wear and tear. This white paper introduces capacitance level switches as an accurate and reliable alternative for water/oil interface detection.

-

Secondary Containment Requirements For Aboveground Storage Tanks

Read about aboveground storage tanks, which are a common sight in manufacturing across the United States.

-

Tangential Flow Separation: A New Way To Treat Waste

Can “leaky hoses” really be considered an innovation? The answer is yes — when applied (ingeniously) for liquid/solids separation.

-

When Chemistry Meets Water Innovation

Nobel-winning molecular materials are poised to reinvent purification, desalination, and reuse.

-

What To Know About The EPA's New Effluent Guidelines

The U.S. EPA’s recently released Preliminary 2016 Effluent Guidelines Program Plan indicates the industries and pollutants that the agency has its eyes on for potential future regulation.

-

SuperDisc™ Filtration System Case Study

Glendale Heights Wastewater Treatment Plant discharges treated water to the East Branch of the DuPage River in Illinois.

-

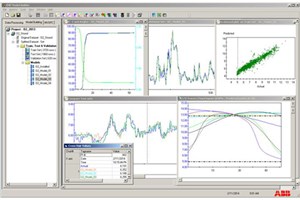

From Insight To Output: How Digital Solutions Can Advance Industrial Water Management

Smart water management is not just a moral responsibility; it’s also a business imperative. Without insights and analytics that empower organizations to act quickly to reach optimal water performance, enterprises stand to lose billions of dollars in asset, water, energy, and operating efficiency.