Temporary bypass keeps plant running

By Alan S. Brown

Managing Editor, Chemical Online

abrown@vertical.net

It's relatively easy to revamp a plant when it involves the main reactors and piping. Usually, engineers chose to close the unit while they connect the new equipment.

But what happens when you need to replace a critical auxiliary unit?

That's the question often faced by chemical manufacturers seeking to replace a water treatment system. After all, your process is still in place and capable of churning out product. Yet it needs process water to maintain operations.

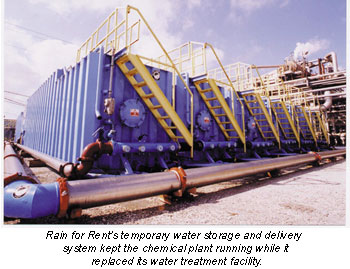

The solution, says Rain for Rent (Bakersfield, CA), often lies in temporary water piping and storage facilities. The company is a major, single source renter of tanks, pipe, pumps, roll-off boxes, and filtration equipment.

The company recently helped a chemical company while it dismantled a 30-year-old, 360,000 gal treated water tank in order to make way for a new one.

A local engineering firm recommended a temporary system to keep the plant online with treated water during the renovation process. The system consisted of 12 interconnected manifold frac portable temporary (frac) tanks designed to receive, store, and supply filtered, clarified, and softened water for the entire facility. It also required hose ranging from 4 in. to 8 in. dia, piping from 8 in. to 12 in. dia, and 12-in. valves.

To implement the ambitious system, they chose Rain for Rent, which was able to provide all the necessary renovation equipment without subcontracting. The Rain for Rent crew installed the temporary system under the direction of an experienced project manager. For the duration of its service, the total equipment package functioned flawlessly, supplying treated water to the entire plant.

In February 2000, the temporary system was replaced with a new 360,000-gallon treated water tank.

For more information: Rick Wright, Rain for Rent, PO Box 2248, Bakersfield, CA 93303. Phone: 661-399-9124. Fax: 661-393-6897.