Hydro International's HeadCell Offers Cost Savings With Next-Generation Upgrade

Hillsboro, Oregon: Hydro International has upgraded its market-leading HeadCell advanced grit removal system with new features that deliver greater design and operational flexibility to help treatment plants save costs and energy use.

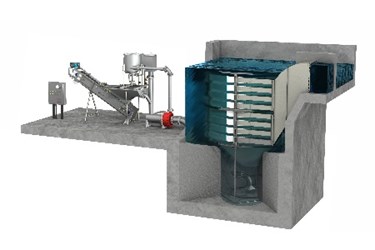

The unique stacked tray design of the HeadCell has consistently met industry demands for high-performance grit removal, often in constrained plant layouts, while minimizing installation and ongoing operating costs. Introducing an innovative intermittent fluidizing and pumping option for all HeadCell sizes and flows has enabled greater diversity in designing a system to reduce electricity consumption and maximize the operating life of equipment. The next-generation HeadCell can now be also configured to accept submersible pumps within the separation chamber.

“By introducing new options for the HeadCell, we are responding to our customers who are increasingly challenged to fit grit separation systems within tight space constraints, as well as to look for greater operating efficiencies by lowering the maintenance burden, saving energy and reducing water usage,” says Marcia Sherony, National Sales Manager of Hydro International in North America.

The HeadCell high-performance grit separation system can now been adapted for intermittent operation by incorporating Hydro International’s fluidizing system into the sump and designing an expanded grit pot collector. The HeadCell operates continuously without power to separate the grit. At predetermined periods, according to site conditions, the fluidizing agitates the collected grit prior to it being pumped to the classifying and dewatering systems.

Intermittent fluidizing and pumping is usually operated on a timed basis, controlled by plant operations personnel based on the grit load and plant demand. Hydro International has developed proven principles for intermittent operation in grit removal during more than 30 years of operating the Grit King hydrodynamic vortex separation system.

“With expert advice, intermittent operation can offer clear advantages for certain sites, for example, where there is a wide difference between peak and average flows , or where there are very low overnight incoming flows with small grit loadings, such as may occur at small plants,” adds Sherony.

The HeadCell also now offers the option of incorporating a submersible pump within the main separation chamber grit collection sump, as an alternative to the standard dry sump model which requires an additional adjacent pump chamber. The submersible pump option is, therefore, ideal for plants where space is at a premium and also can save significant construction without impacting grit removal efficiency. In-chamber submersible pumping is available for the larger models of HeadCell, the 9ft and 12ft diameter units.

“There is no such thing as a ‘one size fits all’ grit removal system,” Sherony advises. “Our customized approach is based on the Advanced Grit Management philosophy which begins by analyzing site-specific requirements before recommending the best combination of grit separation, washing and dewatering technologies.”

The HeadCell is a modular, multiple-tray settleable solids concentrator. Its stacked tray design delivers outstanding grit removal efficiency by providing a large surface area in a small footprint, making it ideal for both new and retrofit applications. Using the Advanced Grit Management philosophy, the HeadCell can be designed to remove 85-95% of all grit entering the plant. It is best used alongside Hydro International’s leading grit washing and dewatering equipment as recommended for the site such as the SlurryCup and GritSnail.

About Hydro International

Hydro International provides cost‑effective solutions for controlling the quantity and improving the quality of water with minimal maintenance. Developed over more than 30 years of research and development, many of Hydro’s award-winning solutions in the water, wastewater and stormwater sectors are based on sustainable vortex technologies. Hydro Americas’ Water and Wastewater division is headquartered in Hillsboro, Oregon, USA. For more information, visit www.hydro-int.com.

“Water and waste water treatment plant engineers with inefficient grit removal systems encounter rising costs for downstream plant maintenance due to grit deposits in basins and pipework and abrasion wear to mechanical equipment. Clogging of aeration tanks in particular can lead to increased energy costs through operating under inefficient conditions.”

Source: Hydro International