A Step-By-Step Approach To Nutrient Removal

By Kevin Westerling,

@KevinOnWater

As stricter ammonia and nitrate regulations get rolled out, the City of Boulder rolls right along with them, improving nutrient removal plant processes in stages to ensure continued compliance.

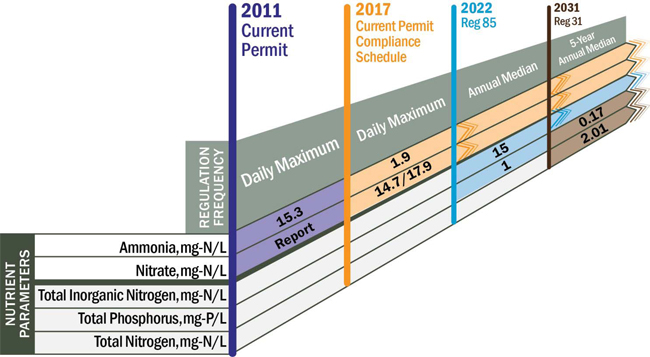

Like many states throughout the U.S., Colorado is cracking down on nutrient loading into its waterways. For the City of Boulder’s 75th Street Wastewater Treatment Facility (WWTF), an activated sludge (AS) biological nutrient removal (BNR) plant that discharges into Boulder Creek, the crackdown will be severe. The 25-MGD capacity (12.5-MGD average) plant, which serves a residential/commercial population of 211,000, must go from their current daily maximum ammonia limit of 15.3 milligrams/liter (mg/L) to 1.9 mg/L in 2017. Furthermore, nitrate, which merely needs to be reported at this stage, will have a maximum daily limit of 14.7 mg/L. But the 75th Street WWTF and its staff of 29 have been through this before. This case study examines the changes Boulder has made — and will make — in response to Colorado’s ever-tightening nutrient regulations.

Regulation: Daily Maximum Ammonia of 15.3 mg/L; Low (Variable) Monthly Average Ammonia of 5.3 mg/L

Process: Modified Ludzack-Ettinger

To protect the state’s waterways from aquatic life toxicity (i.e. fish kills), Colorado implemented the 15.3 mg/L daily maximum limit on ammonia in 2012. In anticipation of the rule, the 75th Street WWTF moved from its previous treatment approach, a trickling filter solids contact (TFSC) process utilizing fixed-film systems including a nitrifying trickling filter, to the current Modified Ludzack-Ettinger (MLE) activated sludge process that was brought online in 2008. The changeover knocked ammonia down from the 5 to 15 mg/L range to the 0.1 to 0.5 mg/L range. While the old system would have kept Boulder under the daily max of 15.3 mg/L, they also have monthly average limits as stringent as 5.3 mg/L, thus driving the need for MLE.

The MLE process is a modification from a conventional activated sludge system, with the addition of an anoxic zone upstream of the aerobic zone. Nitrates converted from ammonia in the aerobic zone (nitrification) become the oxygen source, or food, for bacteria in the anoxic zone (denitrification). The pre-anoxic zone contains a mix of influent wastewater (which serves as the carbon source for the bacteria), return sludge from the clarifier, and nitrate-laden mixed liquor from the effluent end of the aeration tanks.

The series of aeration tanks/basins necessary to accommodate the different zones requires ample area, but that wasn’t an issue for Boulder. “We have the luxury of having a lot of real estate here,” said facility manager Chris Douville. “We have a large facility site with a lot of open space that had yet to be developed, so we weren't extremely limited on footprint.” Also, some old process tanks were available for demolition to enable new construction.

Facility manager Chris Douville oversees the City of Boulder’s 75th Street Wastewater Treatment Facility.

When the MLE process was chosen, it won out over the option of building more nitrification trickling filters and performing denitrification with deep-bed sand filters — not just because it would fit, but because Boulder had a long-range vision for the future. The cost of the 2007-2008 conversion was $28.5 million, comparable to the alternative solution, and funded through municipal bonds. The investment allowed Boulder to achieve full nitrification and thus meet current ammonia requirements, but MLE was also seen as a good, proactive stepping stone for the more advanced nutrient removal processes that are planned as regulations get tighter. Boulder chose to implement partial denitrification in advance to remove some nitrogen before it was mandated by regulations.

And tighter the regulations are getting, with ammonia limits plummeting in 2017 as nitrates are also brought into the fold. But again, Boulder has a plan in place. The city enlisted Brown and Caldwell to help determine the treatment upgrades that will work best for the 75th Street facility in light of upcoming regulations. The evaluation included cost estimates for the work, as well as a suggested timeline for implementation. According to Douville, Boulder is set to move forward with the recommendations, detailed below.

Regulation: Daily Maximum Ammonia of 1.9 mg/L; Daily Maximum Nitrate of 14.7 mg/L

Process: Four-Stage Bardenpho

Like the MLE process, the Bardenpho process suggested by Brown and Caldwell requires multiple aeration zones. Four-stage Bardenpho refers to the four stages of biological treatment: anoxic, aerobic, anoxic, and final aeration. For Boulder, the process can be implemented with only minor internal structural and control modifications to the existing aeration basins used for MLE. A second anoxic zone will need to be constructed for each basin, as will chimney baffles for the addition of carbon, which can be added to either or both anoxic zones. The upgrade will also require new mixers and the relocation of the internal mixed liquor recycle (IMLR) pumps and some of the ceramic diffusers. Finally, the successful implementation of four-stage Bardenpho, according to Douville, is contingent on integration with the facility’s existing SCADA system, which isn’t seen as an issue.

Not bad, all in all… and exactly according to plan. In fact, there was little to consider other than Bardenpho for this round of upgrades. That decision was all but made with the prior MLE installation.

“You can change up the configuration relatively easily, once you have tankage and pumps and channels,” explains Douville, who in addition to being facility manager is a Colorado Professional Engineer (PE), Colorado Certified Water Professional (CWP), and Class A Wastewater Operator. “There's a lot of flexibility with how you reconfigure those basins, especially if the design engineer sets it up well in the beginning, with walls that could be added to or pipe stubs that could be connected later. This kind of thing where you may spend a little bit of money ahead of time, but that allows for future construction — it can be really advantageous.”

With the stepping stone of MLE in place, the conversion to four-stage Bardenpho is projected to cost just under $2 million ($1,951,000). The numbers within that estimate are as follows:

- Capital cost = $1,376,000

- Annual chemical cost = $44,000

- Annual power expense (@ $0.07/kWh) = $22,600

- Annual miscellaneous O&M expenses (routine maintenance, parts, etc.) = $8,300

Accounting for inflation and interest, Brown and Caldwell added the 20-year O&M expenses (the annual costs cited above) — determined to be $1,110,000 in present-day dollars — to the capital cost, then subtracted a salvage amount (60% for non-mechanical equipment after 20 years) to arrive at the final price. Energy costs for the Bardenpho process are projected to be $20,000 to $30,000 more per year than the baseline MLE process, but Douville notes that this is just a modest 3% increase to the facility’s $500,000 to $600,000 annual power bill. The overall cost for the conversion is still low enough that the utility will simply absorb it over time through their regular revenue stream, mainly residential and commercial connection fees and wastewater rates.

Carbon Dating: Finding That Perfect Match

There is the possibility that the true cost could be even lower, since the current estimate is based on methanol as the supplemental chemical carbon source for operations. Additional carbon is necessary for nitrate compliance because the plant doesn’t have enough readily available for the denitrification organisms to feed on and work optimally. But Boulder is still playing the field when it comes to a desirable source.

“We're undecided on the exact type of carbon. The city is interested in exploring alternatives,” said Douville. “Methanol is a common source that a lot of entities are considering or have employed, but it's expensive and it's flammable, and there are safety risks. If we can’t come up with a better or different option, that's what we'll end up with.” Boulder is currently evaluating potential local waste products, such as brewery waste, as an environmentally friendly solution to reduce or eliminate the need for methanol or other chemical products.

Regardless of how the carbon deficit is ultimately resolved, well-fed microorganisms in the four-stage Bardenpho process should ensure compliance with the looming daily maximum effluent requirements for ammonia (1.9 mg/L) and nitrate (14.7 mg/L). The key will be to avoid the peak ammonia and nitrate excursions that the current MLE process is susceptible to.

“Right now our goal is to fully nitrify, and we generally do,” stated Douville, “but we absolutely do have variation in our loading, and that's when we'll have these little excursions of ammonia. Sometimes it's an excursion up to 0.5 or 1, but we do have excursions of 3, 5, or 10 mg/L on occasion.” Come 2017, such excursions could result in fines for noncompliance, which is why Boulder continues to stay ahead of the curve with its system upgrades.

Indeed, when the moment arrives, the 75th Street WWTF will be ready. Construction for the Bardenpho transition is planned for 2015, while startup and testing will be finalized in 2016. The story doesn’t end there, as even more regulations are scheduled to be enacted in 2022 and 2031 (see figure below). Of course, the ever-prepared Boulder facility already has a plan for those regulations as well (fodder, perhaps, for future Water Online case studies).

The march of environmental regulations, in graphic detail

“He Who Fails To Plan Is Planning To Fail”

Winston Churchill said it first, but Chris Douville and the City of Boulder are heeding this famous quote every day. Not only should a long-range plan for compliance be put in place, but each step should be considered in context of what’s coming next — MLE to four-stage Bardenpho being a prime example. The 75th Street WWTF figured out that foresight can save the municipality (and thus the ratepayers) considerable money, as well as future headaches.

Now, if they could only meet a nice carbon source they like…